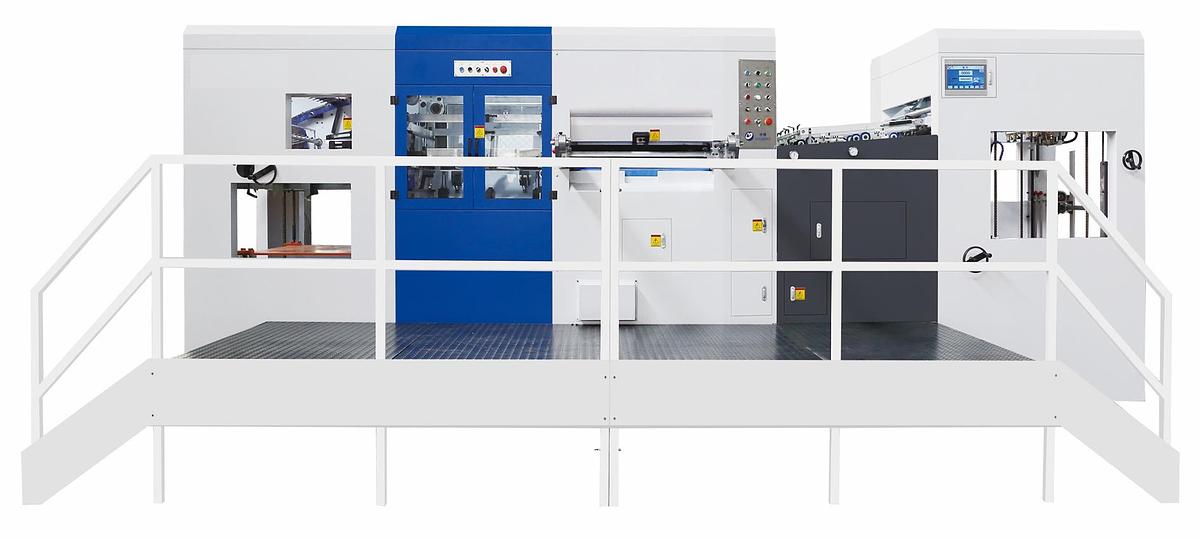

Diecutter with Stripping 1080CS

Diecutter with Stripping 1080CS

Location:Bologna, Italy

Available quantity:1

or

Call +359 2 492 9330

Description

Machine Features

- High-Speed Operation: Achieves up to 7000 cycles per hour with a die-cutting precision of ±0.1 mm.

- Single-Pass Waste Removal: Removes all paper waste and non-essential edges (excluding openings) during die-cutting, reducing labor and increasing production efficiency.

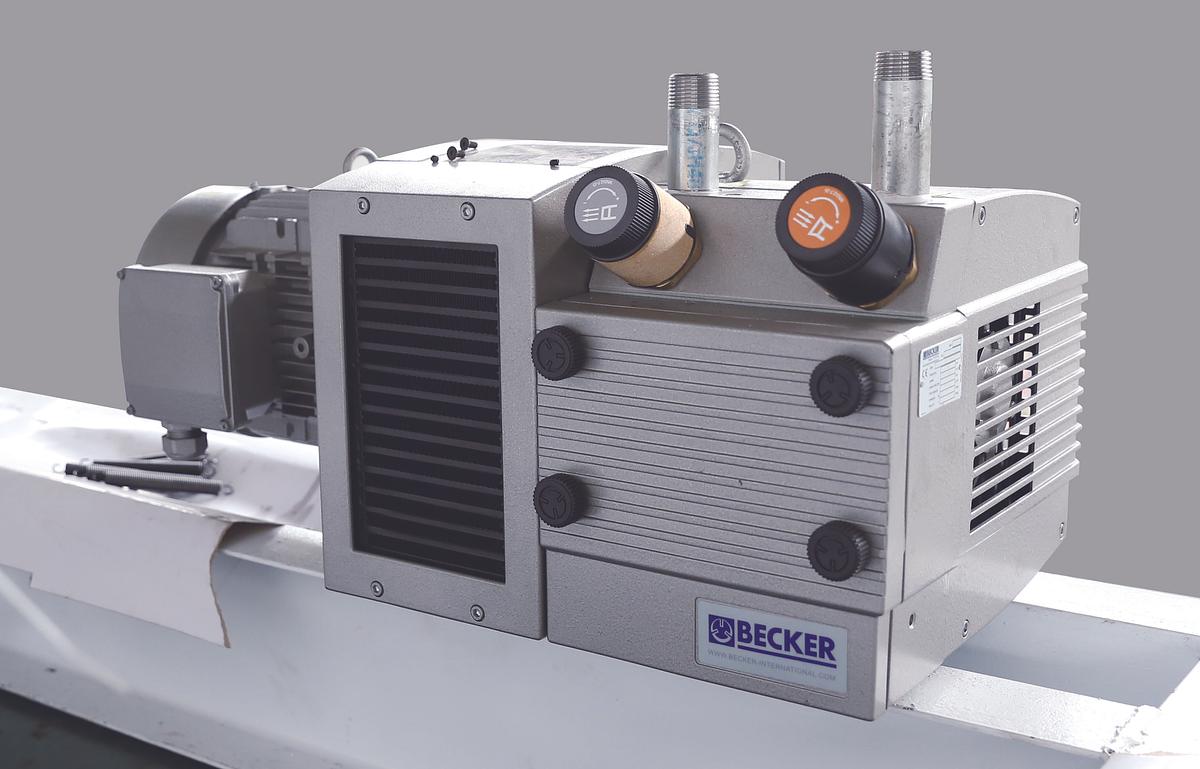

- Feida Head Paper Feeding: Equipped with four suction and four delivery heads for robust paper feeding. Adjustable suction nozzles optimize feeding smoothness.

- Pre-Stacking Mechanism: Combined with primary and auxiliary feeding systems, ensures continuous feeding without interruptions.

- Inclined Feed Table: Advanced paper pressing device facilitates smooth feeding of deformed corrugated board, enhancing die-cutting speed.

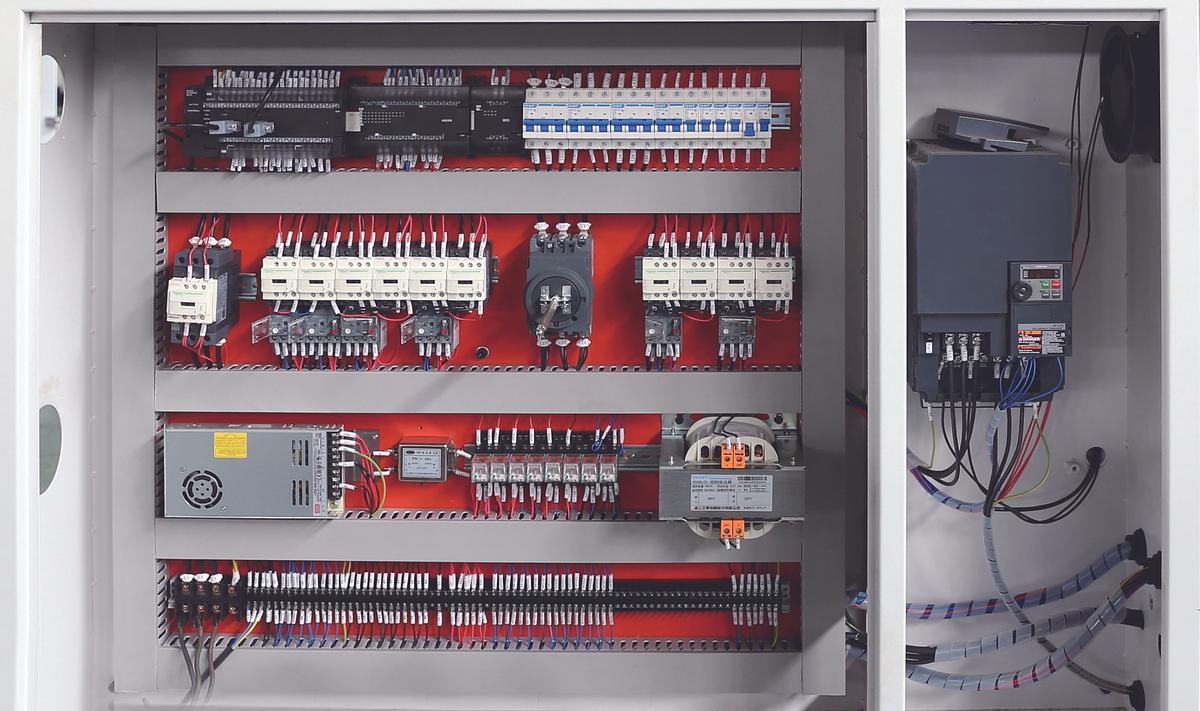

- PLC Control: Operated via a dual-station touchscreen with a human-machine interface, ensuring precise movements and easy adjustments.

- Dual Touchscreen Monitoring: Both the operating and delivery areas feature human-machine interface screens for real-time machine status monitoring, dynamic detection of input/output points, and simplified troubleshooting.

- Electric Front Lay: Four electric front lays with four photoelectric detection switches allow automatic precision adjustments without stopping, ensuring accurate paper positioning and reducing waste.

- Dual-Purpose Side Lay: Integrated push-and-pull design, adjustable for die-cutting cardboard and corrugated board, with photoelectric detection for precise positioning.

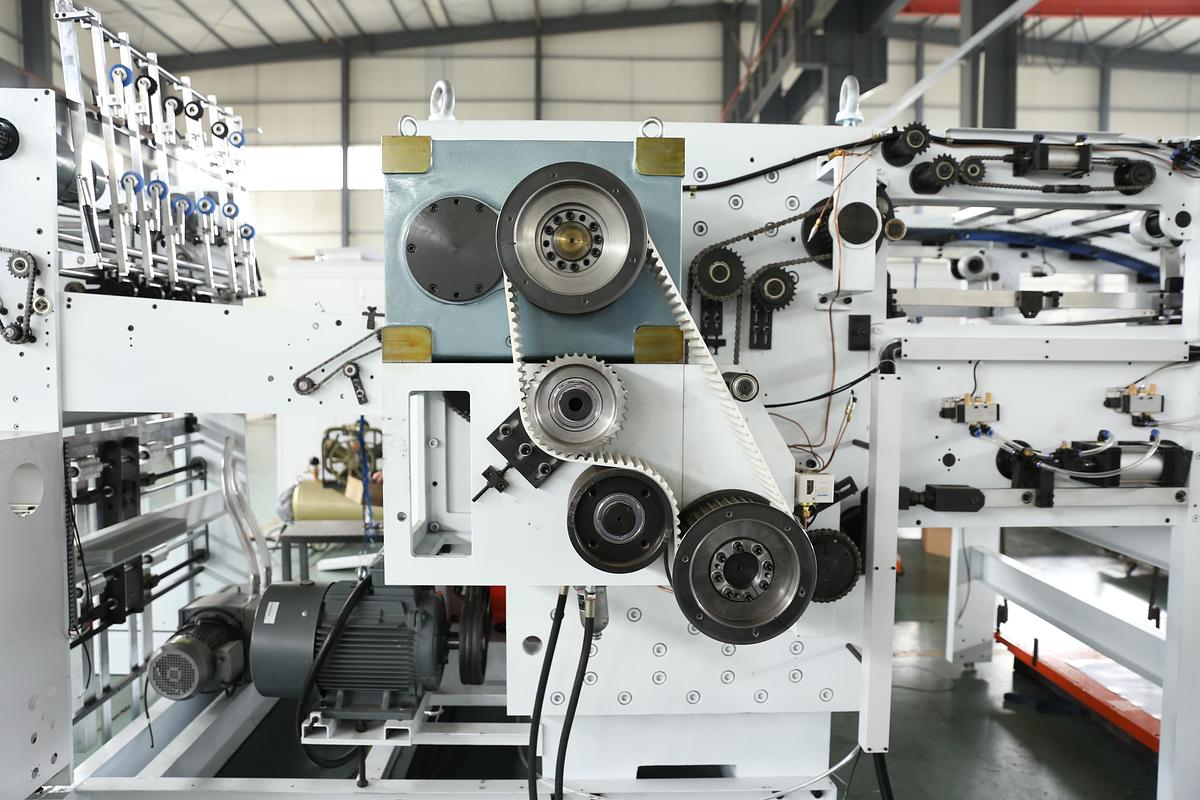

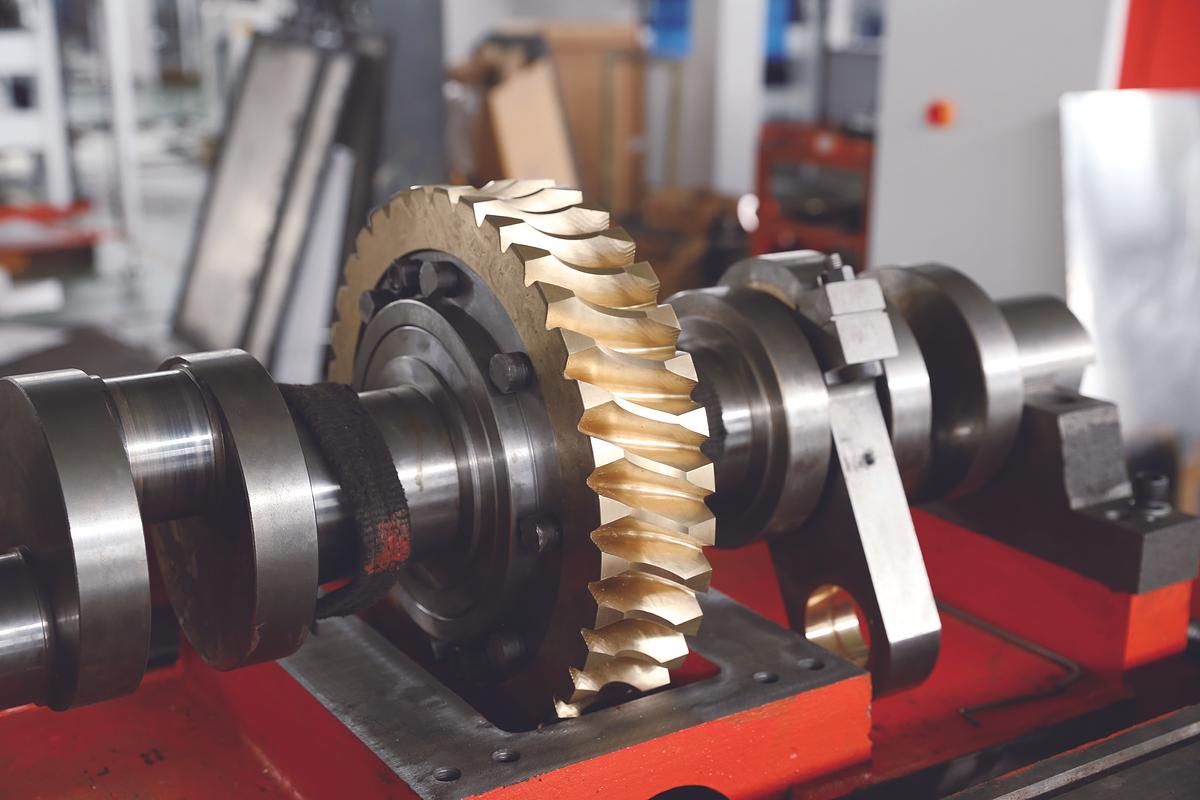

- High-Precision Cam Indexing: Ternary cam intermittent mechanism ensures smooth gripper bar operation.

- Pneumatic Die Frame Locking: Ensures precise and user-friendly positioning of the die frame and cutting plate.

- Digital Pressure Adjustment: Lifting pressure is adjusted via an electric digital display on the touchscreen for simple and precise control.

- High-Precision Gripper Chain: Manufactured by Iwis (Germany), pre-stretched for accuracy and durability.

- Aviation-Grade Aluminum Gripper Bar: Reinforced and thickened for stability, with adjustable devices to compensate for chain wear.

- High-Strength Cast Iron: Key components (main wall, upper, mobile, and lower platforms) are made of high-strength nodular cast iron, heat-treated to prevent deformation and ensure stable pressure.

- Adjustable Mobile Platform: Four individually adjustable feet for optimal leveling.

- Forced Lubrication System: Equipped with oil speed and flow sensors, triggering alarms and shutdowns for low pressure to protect joints.

- Timed Lubrication System: PLC-controlled touchscreen ensures precise, timed, and quantitative lubrication of transmission chains.

- Adjustable Brushes and Flattening Devices: Stabilize finished products in the delivery area.

- Air Blowing Device: Ensures smooth and orderly delivery, especially for thin paper.

- Pneumatic Sampling: Enables quick and convenient inspections in the delivery area.

Specifications

| Manufacturer | BBS |

| Model | 1080CS |

| Condition | New |

| Stock Number | 6258488 |

| Max. sheet size: | 1080x780mm |

| Min. sheet size: | 400x360mm |

| Max. die-cutting size: | 1060x760mm |

| Max. Pressure: | 400N/cm2 |

| Thickness of sheet: | Cardboard:0.1-2.0mm - corrugated board:≤5mm |

| Max Feeder pile height: | 1500mm |

| Max Delivery pile height: | 1500mm |

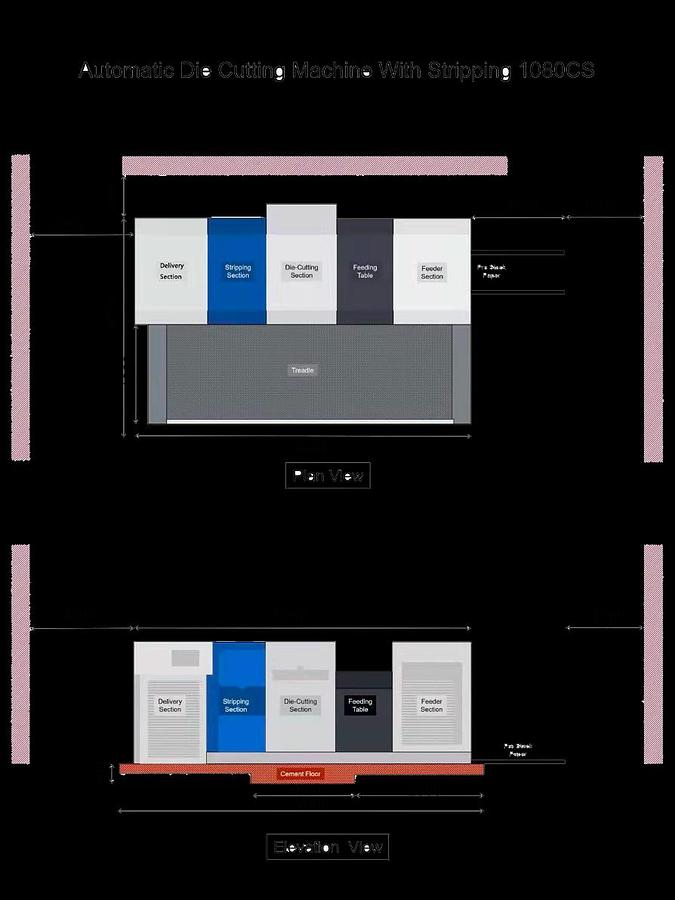

| Overall dimensions: | 5500x4000x2300mm |

| Max. die-cutting speed: | 7000S/H(cardboard) - 6000S/H(corrugated board) |

| Max stripping speed: | 6000S/H |

| Die-Cutting Precision: | ≤±0.10mm |

| Min gripper needle size: | 8mm |

| Rate power: | 22KW |

| Weight: | 18T |

| Dimension(L x W x H): | 6600mm*4000mm*2300mm |