HIGH-SPEED AUTOMATIC LAMINATOR

HIGH-SPEED AUTOMATIC LAMINATOR

€77,000 (EUR)

Location:Bologna, Italy

Available quantity:1

Description

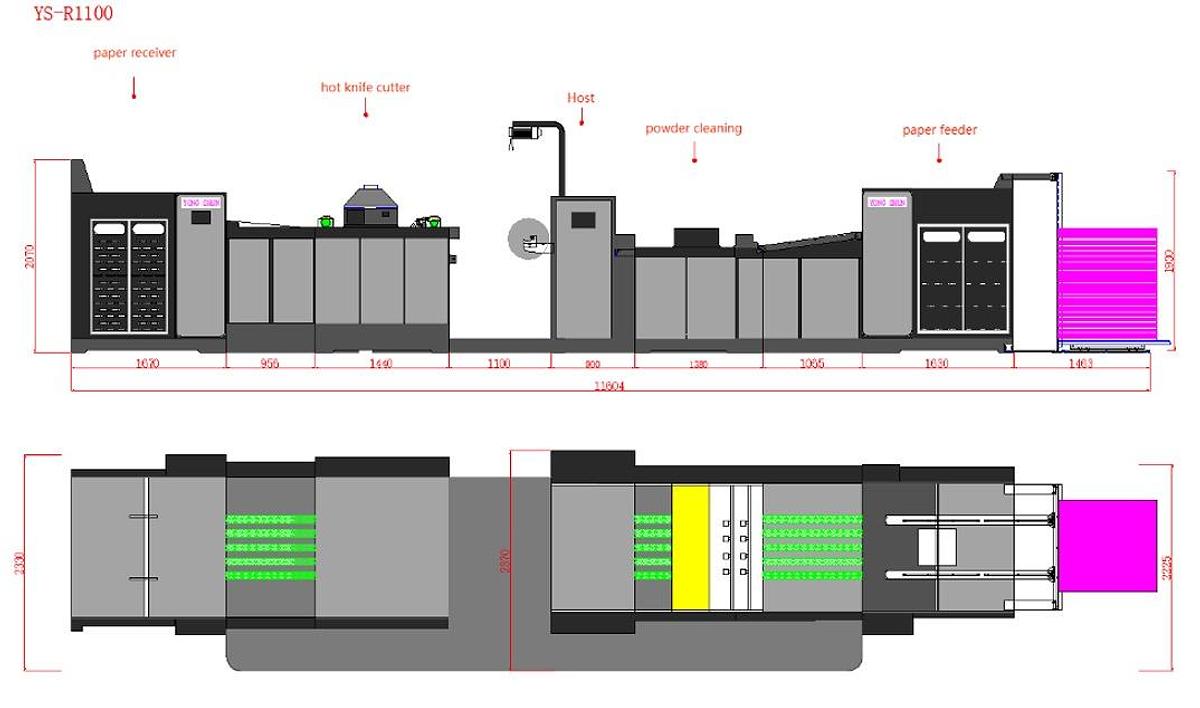

YS-R1100 – High-Speed Automatic Laminating Machine for Industrial Performance

The YS-R1100 is a high-speed, energy-efficient automatic laminating machine designed to meet the most advanced production requirements in the printing and packaging industry.

Engineered for intensive and continuous operation, the YS-R1100 is ideal for laminating posters, books, catalogs, promotional materials, folding cartons, packaging products and paper bags, ensuring stability, precision and excellent finishing quality even at maximum operating speeds.

High Performance and Full Process Control

With a working speed of up to 100 m/min and a pre-coated lamination system, the YS-R1100 delivers high productivity while optimizing energy consumption.

The Ø 450 mm laminating roller, equipped with intelligent electromagnetic heating and an internal oil heating system, guarantees uniform temperature distribution and a maximum pressure of up to 10 tons, ensuring consistent lamination quality even on demanding substrates.

Precise and Reliable Paper Handling

The feeding unit features a high-precision feeder with four blowing and four suction points, supported by servo control, maintaining sheet alignment within ±2 mm even at high speeds.

The non-stop pre-stacking system allows continuous paper loading without stopping the machine, significantly reducing downtime.

The machine handles sheet sizes from 350 × 300 mm up to 1080 × 1000 mm, with paper weights ranging from 105 to 500 g/m², suitable for offset paper, coated paper and grey board.

Superior Quality with Hot-Knife Cutting Technology

The YS-R1100 can be equipped with an advanced hot-knife cutting system, which completely eliminates film tails and guarantees clean, precise edges on PET, OPP and BOPP films.

This technology delivers laminated products that are immediately ready for further finishing processes such as creasing, UV printing and die-cutting, without additional trimming operations, resulting in significant savings in time and labor.

Automation, Safety and Ease of Operation

The entire machine is managed by a PLC control system with HMI interface, synchronizing inverters and servo motors to ensure stable operation and intuitive control, often requiring only one operator.

The intelligent delivery system features automatic speed adjustment and waste rejection, maintaining smooth production flow and minimizing material loss.

Premium Components and Long-Term Reliability

The YS-R1100 is built with high-quality components from leading international brands such as Siemens, Schneider, Omron, Baumer, Becker and NSK, ensuring long-term reliability, easy maintenance and global spare parts availability.

Oprionals:

- Cutting with a chain knife: €10,500

- Cutting with a hot knife: €12,900

- Dust removal: £4,000

Specifications

| Manufacturer | BBS |

| Model | YS-R1100 |

| Condition | New |

| Stock Number | BBS251224 |

| Model: | YS-R1100 |

| Maximum sheet size: | 1080 x 1000 mm |

| Minimum sheet size: | 300 x 350 mm |

| Paper thickness: | 100-500 g/m² |

| Paper height in the feeder: | 1350 mm |

| Output paper height: | 1270 mm |

| Speed: | 20-100 m/min |

| Total power: | till 35 kW (power varies depending on configuration) |

| Dimensions: | 11000 x 2370 x 2100 mm |

| Peso: | 7000 KG |

| Applicable paper types: | Coated paper, metallic coated paper, white paper with grey backing |

| Types of films that can be applied: | Opp - BOPP |

| Rolling method: | Pre-coated film |

| Operating power: | 15-25 Kw |

| Standard configuration: | 1. Rotating knife |

| Opzionale: | Cutting with a chain knife; Cutting with a hot knife; Dust removal |