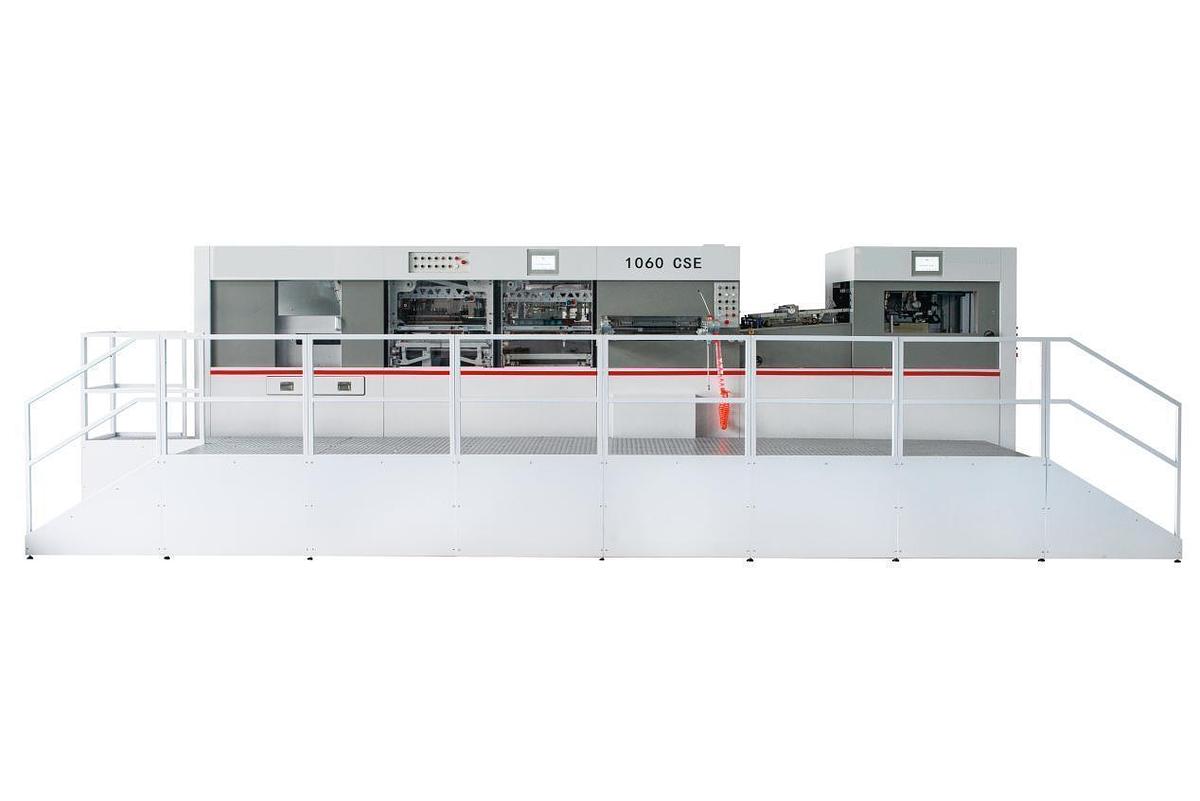

BBS 1060CS-E Die Cutting and Blanking

BBS 1060CS-E Die Cutting and Blanking

Location:Bologna, Italy

Available quantity:1

Description

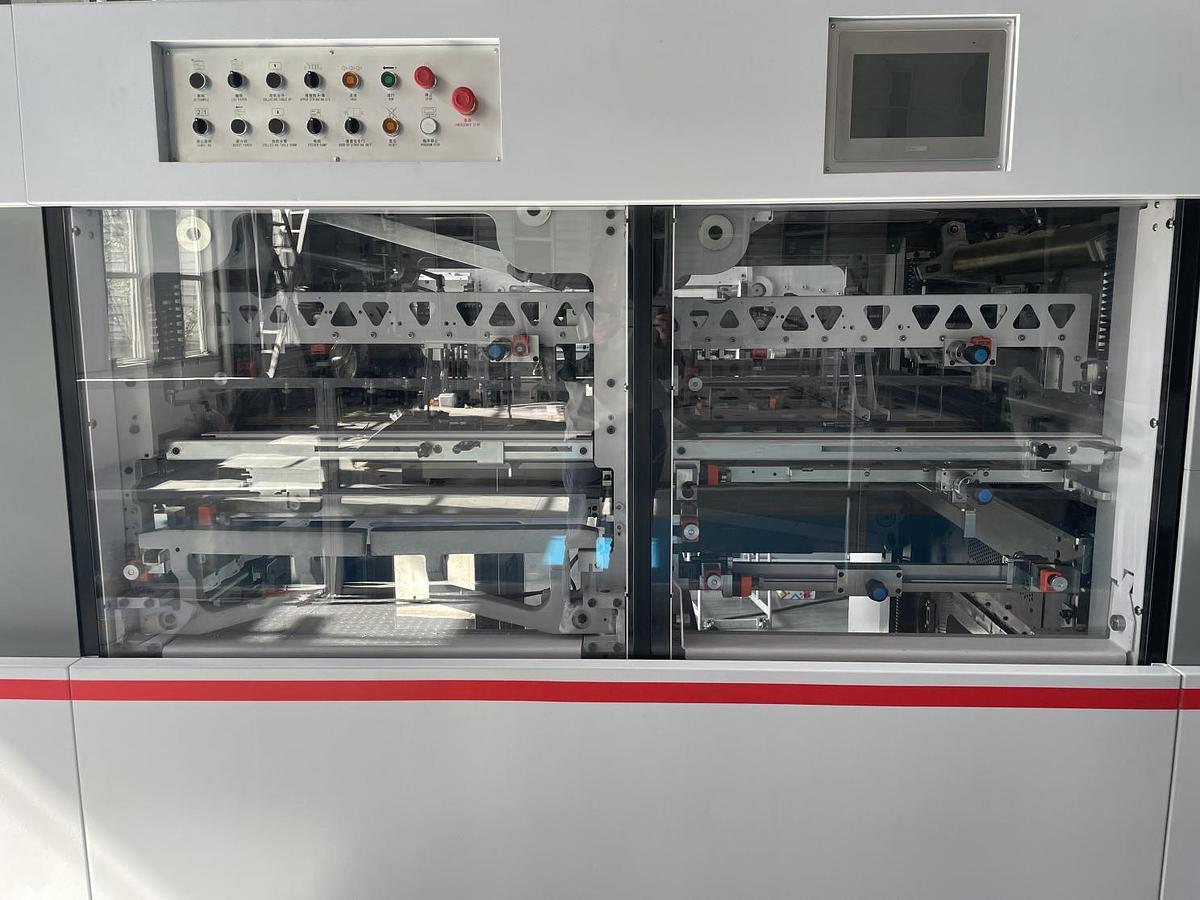

The 1060CS-E is a high-performance automatic flatbed die cutting and blanking machine designed for cartonboard and corrugated board processing.

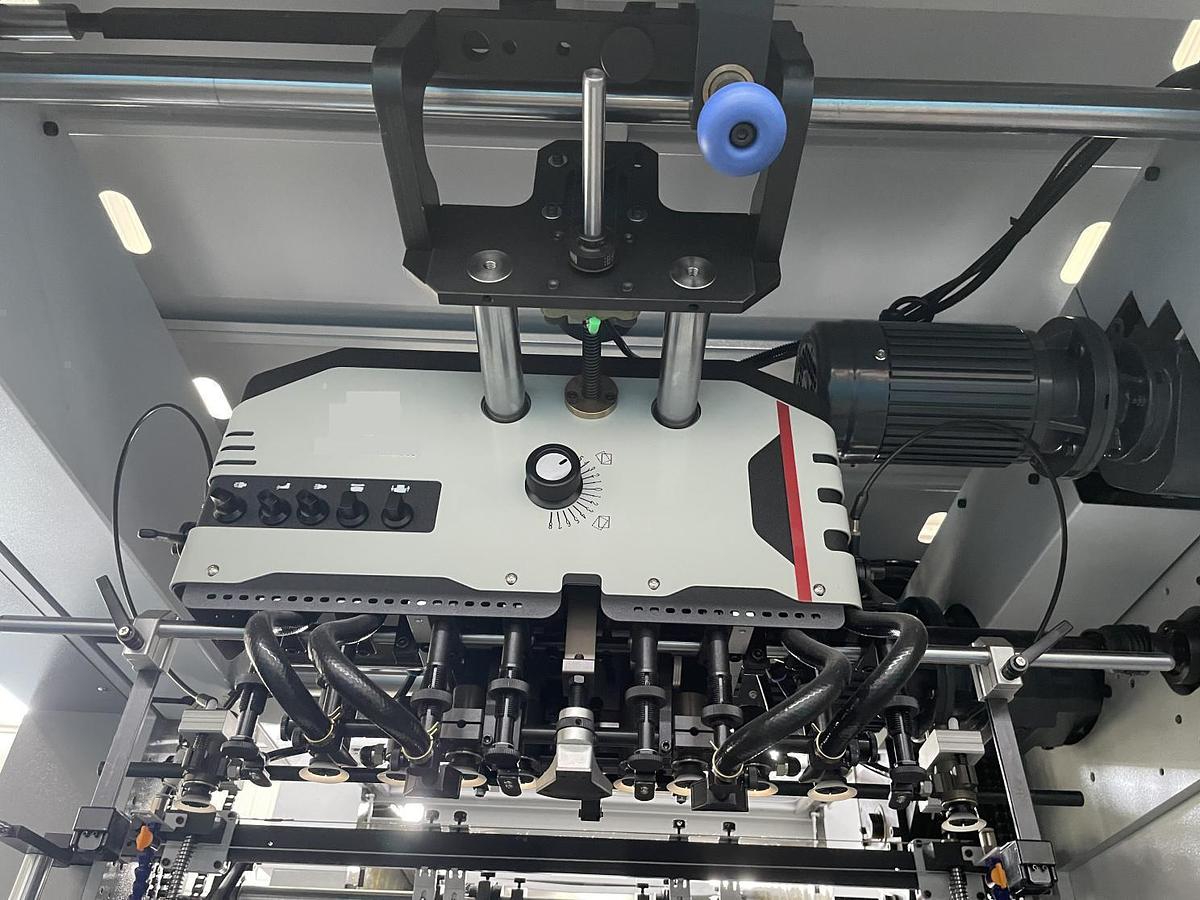

Engineered for precision, stability, and high productivity, this model integrates feeding, die cutting, stripping and delivery units in a fully automated workflow.

The machine is ideal for packaging converters requiring clean waste removal, fast job changeover, and reliable continuous production. With advanced feeder technology, ultrasonic double-sheet detection, and centralized stripping positioning, the 1060CS-E ensures accurate registration and perfectly cleaned blanks ready for the next production stage.

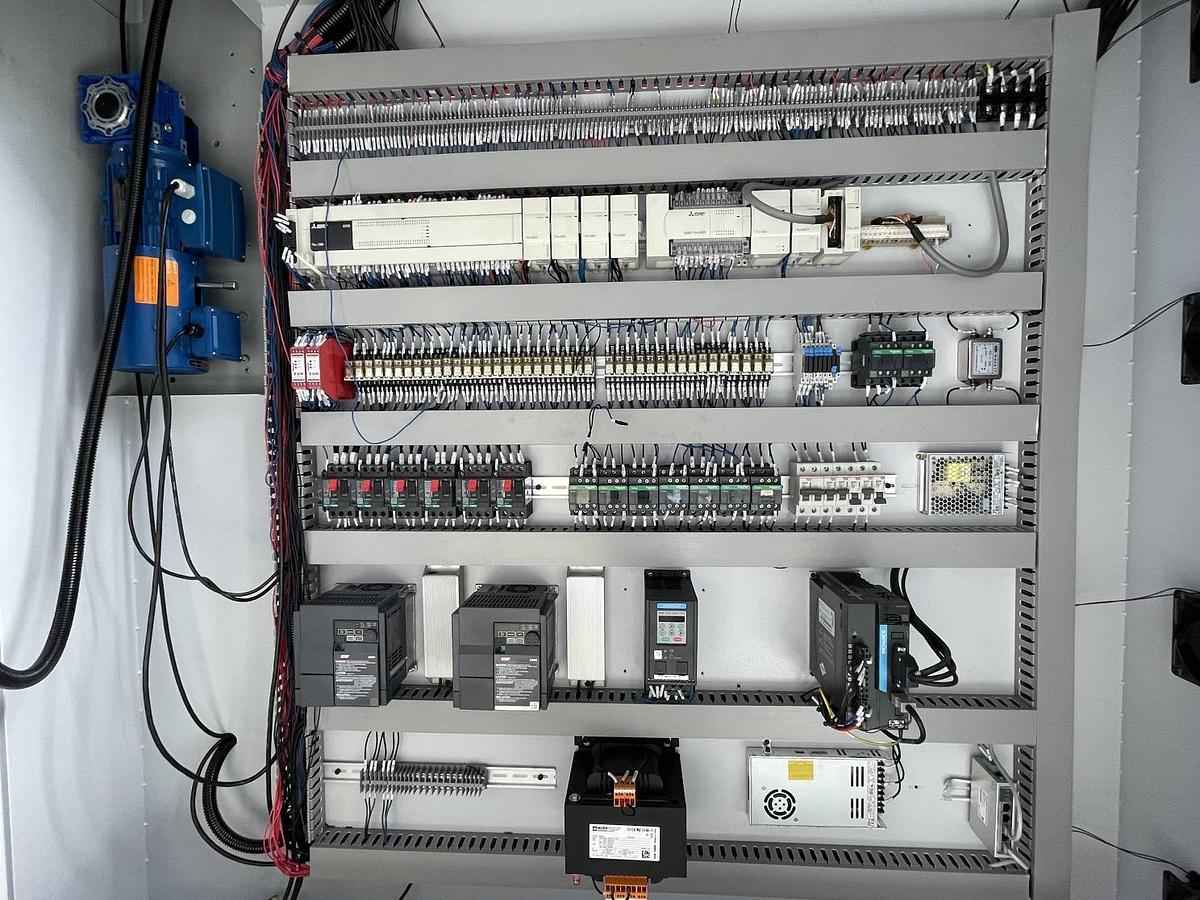

Its heavy-duty frame structure and high-quality components guarantee long-term durability and consistent performance even in demanding industrial environments.

Specifications

| Manufacturer | BBS |

| Model | 1060CS-E |

| Condition | New |

| Stock Number | BBS251310 |

| Paper Range: | Paperboard 90–1000 gsm |

| Corrugated Thickness: | <= 4 mm |

| Max. sheet size: | 1060 × 760 mm |

| Min. sheet size: | 400 × 350 mm |

| Inner chase size: | 1080 × 770 mm |

| Max. Die Cutting Size (including waste edge): | 1060 × 745 mm |

| Minimum gripper margin: | 9 – 17 mm |

| Cutting rule height: | 23.8 mm |

| Minimum waste edge between double knives: | 5 mm |

| Max. Die Cutting Pressure: | 300 tons |

| Max. mechanical Speed: | 9,000 sheets/hou |

| Max. Height of Feeding Pile: | 1800 mm |

| Max. Height of Feeding Pile with no-stop: | 1520 mm |

| Max. Height of Delivery: | 1580 mm |

| Main Motor: | 15 kW |

| Total Power: | 23 kW |

| Overall demensions: | 6415 × 4520 × 2640 mm |

| Machine Weight: | 22.000 kg |